> Overview: News

> Overview: Service

> Overview: About

If you engage in numerous non-standard operating practices when operating an excavator, this will directly impact its service life. The previous two instalments covered operations that cause significant damage to the bucket and undercarriage. This instalment will outline situations unsuitable for excavation work – remember, never operate without considering the consequences.

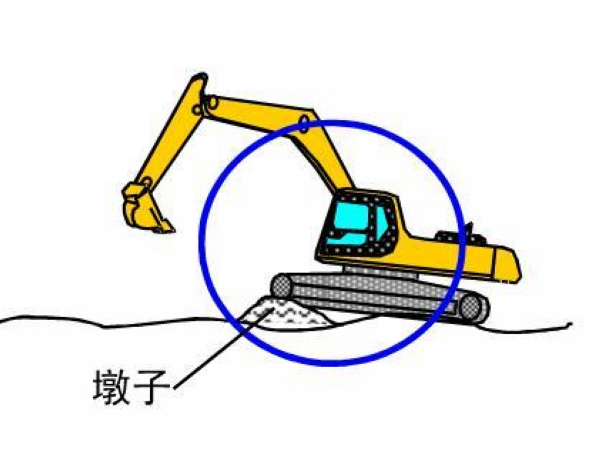

1. Commencing work while the excavator is unstable

The first incorrect practice: As illustrated above, commencing excavation while the machine is unstable is inadvisable. Such operation subjects the frame to repeated twisting and deformation. Prolonged exposure to these stresses can cause cracks to form in the frame, significantly shortening its service life.

The correct approach under these conditions is shown in the diagram: create a mound of earth in front of the excavator's tracks to stabilise the machine, enabling safe operation.

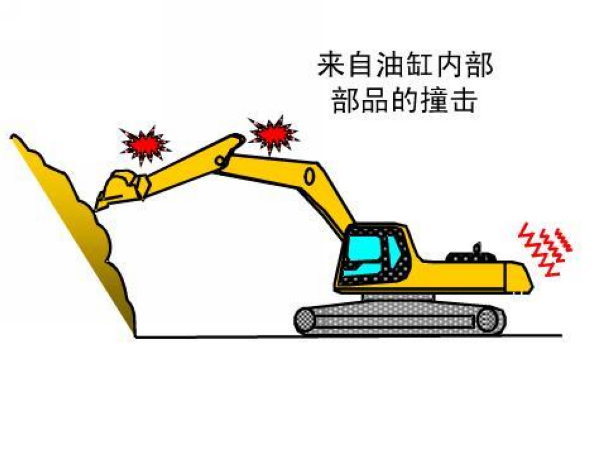

2. Operating at Extreme Cylinder Extension

The second damaging practice involves extending the hydraulic cylinder to its fullest extent during excavation, as illustrated. This places excessive load on the working cylinder and frame. Impacts from the bucket teeth and various pins may cause internal cylinder damage and adversely affect other hydraulic components.

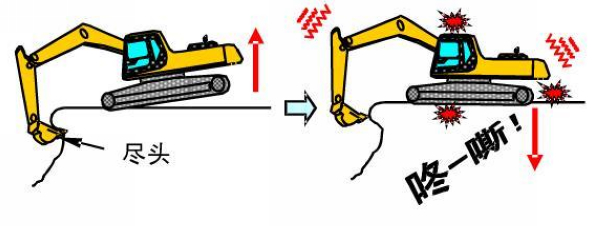

3. Excavating with rear tracks lifted

The third incorrect practice involves utilising the upward force from the rear of the excavator's undercarriage to perform digging tasks. When the bucket separates from the rock and the undercarriage descends, substantial loads are imposed on the bucket, counterweight, frame, and slewing ring, readily causing damage. The track-lifted operation depicted in the illustration is particularly detrimental to the excavator.

Simply put, when excavating with the rear tracks lifted, the combined force of hydraulic pressure and machine weight acts on the pins, their peripheral areas, and the bucket, making working components prone to cracking. The subsequent track descent also delivers substantial impact to the rear counterweight, potentially causing main frame deformation, slewing ring damage, and other failures.

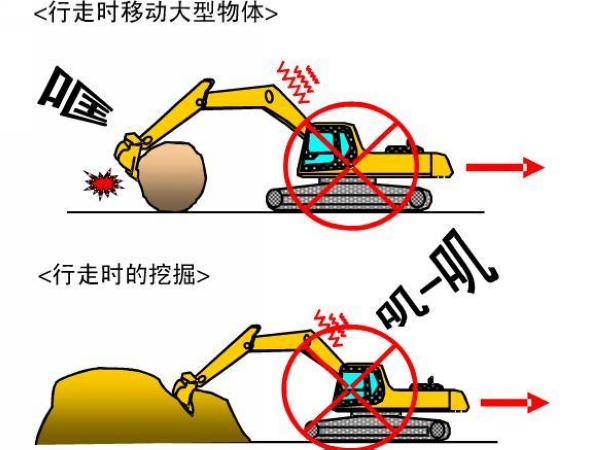

4. Utilising traction force for moving large objects and excavation work

Finally, a particularly damaging operating practice involves employing the machine's traction force to move substantial objects or perform excavation tasks whilst working (as illustrated above). This subjects the working equipment, pins, frame, and bucket to excessive stress, significantly reducing their service life. Such practices should be avoided whenever possible.

2025-01-21

2020-07-08

2020-08-24

2020-01-21

2019-12-25

2019-11-01

2021-02-01

2020-10-26

2021-01-14

2020-12-11

2020-07-04

2020-09-30