> Overview: News

> Overview: Service

> Overview: About

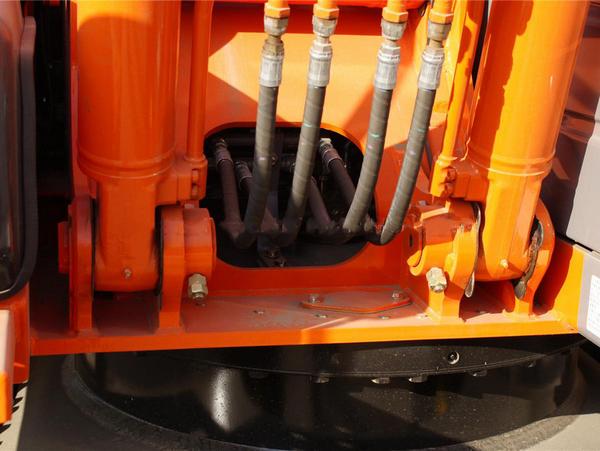

Hydraulic pipe burst is a common failure in

excavator operations, not only leading to hydraulic oil leakage, high

maintenance costs, but also may cause delays in the project. Industry experts

pointed out that the burst pipe is mostly triggered by the following reasons:

1.Poor quality fittings and process defects

The use of low-quality hydraulic pipe or

buckling process poor fittings, sealing and reliability is not enough, easy to

leak oil or even burst pipe. It is recommended that the replacement of regular

brands of hydraulic pipes and fittings.

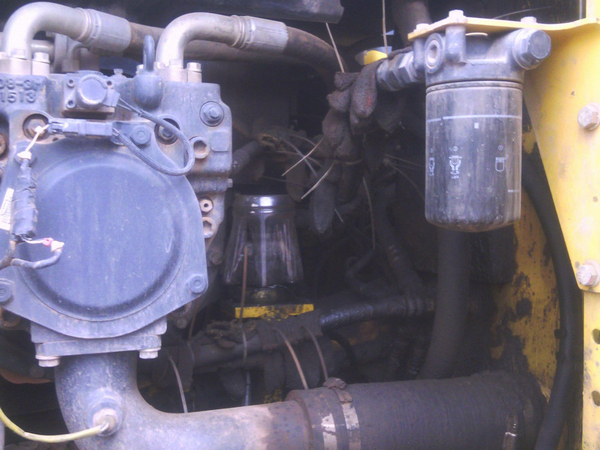

2.System pressure and temperature

abnormality

Hydraulic system preset pressure is too

high or the hydraulic oil temperature is too high, will accelerate the aging of

seals, and even lead to pipeline expansion rupture. Regular monitoring of the

pressure value is required to avoid high temperature operation.

3.Mixing and improper operation of

hydraulic oil

Mixed use of different grades of hydraulic

oil (such as 46 # and 68 # mixed) will destroy the stability of the fluid,

increasing the pressure of the pipeline; rough operation of the transient

impact pressure will also accelerate the failure of the pipeline.

4.Corrosion and vibration fatigue

Hydraulic pipe long-term contact with

diesel and other corrosive liquids, or due to abnormal vibration lead to loose

pipe clamps, wear and tear, and ultimately lead to pipe burst. Daily need to

clean the pipeline and check the fixtures.

Emergency three-step method

If the sudden burst pipe, should be immediately:

1.Stop the machine to reduce pressure: turn

off the engine after the bucket falls to the ground to reduce the loss of

hydraulic oil;

2.Temporary repair: clean the rupture of the

low-pressure pipeline, use anaerobic adhesive or cloth wrapped seal;

3.Adjustment of oil circuit: swap oil pipes

of the same specification (unbroken pipes bear high pressure), and maintain the

operation.

Expert reminder: temporary measures are

only for emergency purposes, you need to replace the new pipe and replenish the

hydraulic oil as soon as possible to avoid secondary failure.

Prevention is better than remedy

Regular replacement of standard hydraulic

fluid, standardised operating procedures and enhanced equipment inspection can

significantly reduce the risk of pipe burst. Practitioners need to remember:

short-term cost savings can be more costly.

2025-01-21

2020-07-08

2020-08-24

2020-01-21

2019-12-25

2019-11-01

2021-02-01

2020-10-26

2021-01-14

2020-12-11

2020-07-04

2020-09-30