> Overview: News

> Overview: Service

> Overview: About

Operating an excavator in extreme summer heat is already demanding. Without a functional air-conditioning system, the cab temperature can be nearly the same as outside, making long working hours exhausting and even dangerous. Air conditioning is no longer a luxury—it is a necessity. However, if the system fails during peak heat, it can seriously affect operator comfort, efficiency, and health. Therefore, proper daily use and regular maintenance of the excavator air-conditioning system are essential to minimize failures and ensure reliable cooling performance.

1. Control the Temperature Difference to Reduce Fuel Consumption

During daily operation, the air-conditioning temperature should not be set too low. Excessive temperature differences between the inside and outside of the cab can easily cause colds, coughing, fever, fatigue, and reduced concentration for the operator. In addition, lower temperature settings increase engine load, which directly leads to higher fuel consumption.

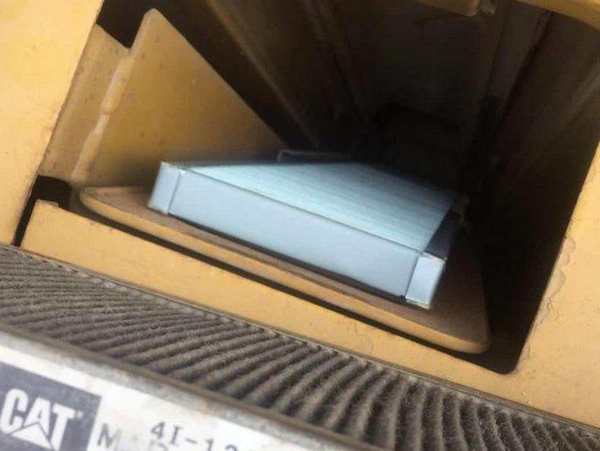

2. Prevent Blockage by Regularly Cleaning or Replacing Filters

Air-conditioning filters require routine maintenance. Under normal conditions, filters should be cleaned every 500 operating hours. If the excavator works in dusty environments, cleaning should be done more frequently. Dust and debris accumulation can block airflow through the filter, significantly reducing cooling efficiency. Filters must also be replaced at regular intervals.

3. Clean and Inspect the Condenser Fins

Besides filters, the air-conditioning condenser fins must be cleaned and inspected regularly. Mud, dust, and debris on the condenser surface should be removed promptly to prevent blockage and maintain proper heat dissipation, ensuring effective cooling performance.

4. Remove Other Dust and Debris

Additional cleaning includes removing dust from radiator fins, as excessive buildup increases engine fuel consumption. Debris near the air intake should also be cleared in time, as blockages will reduce airflow and weaken cooling output.

5. Check Compressor Belt Tension

The air-conditioning compressor belt tension should be checked every 250 operating hours. Apply approximately 6.2 kgf of pressure at the midpoint between the drive pulley and compressor pulley—the belt deflection should be 6.3–8.7 mm. Refrigerant levels should also be inspected regularly, as low levels will reduce cooling effectiveness.

6. Inspect the System Even During Off-Season

Although air conditioning is mainly used in summer, it should not be ignored during other seasons. When idle, the system should be operated for 3–5 minutes each month to prevent failures caused by long-term inactivity.

2025-01-21

2020-07-08

2020-08-24

2020-01-21

2019-12-25

2019-11-01

2021-02-01

2020-10-26

2021-01-14

2020-12-11

2020-07-04

2020-09-30