> Overview: News

> Overview: Service

> Overview: About

With the arrival of the Start of Winter

solar term, the cold winter is about to sweep the country. For heavy machinery

and equipment such as excavators, maintenance and maintenance are particularly

important in winter. In order to ensure that the excavator can operate

efficiently and stably in winter and avoid various potential failures and

damage, the following is our winter excavator maintenance guide to help users

avoid ten common mistakes.

1.Water too early or not put cooling water

Premature release of cooling water may

cause the excavator body to be suddenly attacked by cold air when the

temperature is high, resulting in sudden shrinkage and cracks. The correct way

is to run at idle speed before flaking out, and then release water after the

cooling water temperature drops below 60 ° C, and ensure that the remaining

water in the body is completely discharged.

2.The use of inferior fuel oil

Low temperature in winter will make the fluidity

of diesel become worse, viscosity increase, resulting in poor atomization and

combustion deterioration. Therefore, light diesel with low freezing point and

good ignition performance should be selected, and the freezing point should be

lower than the local minimum temperature of the current season of 7-10℃.

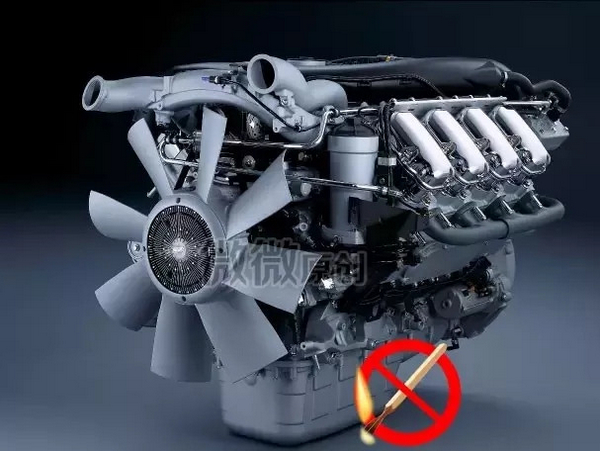

3. Open flame ignition start excavator

Using an open flame to start the excavator

will not only damage the air filter, but also lead to abnormal wear of the

piston, cylinder and other parts. The correct way to start is to start the

excavator through the preheating system or auxiliary starting equipment.

4.Open fire baking oil pan

Baking oil pan over open flame may cause

oil deterioration and scorching, reducing lubrication performance. In winter,

oil with low freezing point should be selected, and the method of external

water bath heating is used to improve the oil temperature.

5. Improper starting method

The excavator needs to be fully preheated

before starting to avoid the wear caused by the oil sinking and the excessive

gap between the parts. The best preheating time is 15-20 minutes to ensure that

the oil and hydraulic oil temperature reaches the appropriate range before

operation.

6. Low temperature load operation

The diesel engine should be idled at low

and medium speed for a few minutes immediately after starting, and then put

into load operation when the cooling water temperature reaches 60 ° C, in order

to avoid serious wear caused by low body temperature and large oil viscosity.

7.Do not pay attention to the body heat

preservation

The low temperature in winter easily leads

to excessive cooling when the diesel engine works. Therefore, it should be

equipped with cold protection equipment such as insulation cover and insulation

curtain, and check whether the work of the temperature saver is normal.

8.Stop the machine flameout

Immediately after shutdown, idle operation

should be 5-10 minutes, especially with turbocharged diesel engines, to avoid

premature damage of the turboshaft due to lack of oil lubrication and cooling.

9. Butter is not beat on time

Not filling butter on time will cause the

butter oil seal to fail to seal, increase the wear between the friction parts,

and affect the operation accuracy and work efficiency. Therefore, the butter

should be filled on time and the condition of the butter oil seal should be

checked regularly.

10. The excavator is parked at will

When excavators are parked, they should

choose flat terrain to avoid problems such as insufficient oil pressure and

high temperature of the engine. Especially when parking in places with large

slopes, measures should be taken to ensure the stability of the excavator.

Through the implementation of the above ten misunderstandings and correct maintenance methods, it can be ensured that the excavator can run efficiently and stably in winter, prolong the service life of the equipment, and improve the construction efficiency. It is hoped that the majority of users can pay attention to the maintenance of excavators in winter and provide a strong guarantee for the successful completion of construction tasks.

2025-01-21

2020-07-08

2020-08-24

2020-01-21

2019-12-25

2019-11-01

2021-02-01

2020-10-26

2021-01-14

2020-12-11

2020-07-04

2020-09-30